Imagine this: you’re on the final stretch of your OSHA 30 training, feeling the pressure mounting as you prepare for the exam. You’ve diligently attended each session, absorbing knowledge about workplace safety and hazard recognition. Yet, a lingering sense of doubt creeps in – will you be able to recall everything you’ve learned? What if you stumble on a tricky question? This fear is understandable, as passing the OSHA 30 exam is crucial for your career advancement and ensuring a safe working environment. Thankfully, you don’t have to navigate this journey alone. This article will empower you with the knowledge and strategies to confidently face the OSHA 30 final exam, leaving you with a sense of accomplishment and a clear understanding of click safety principles.

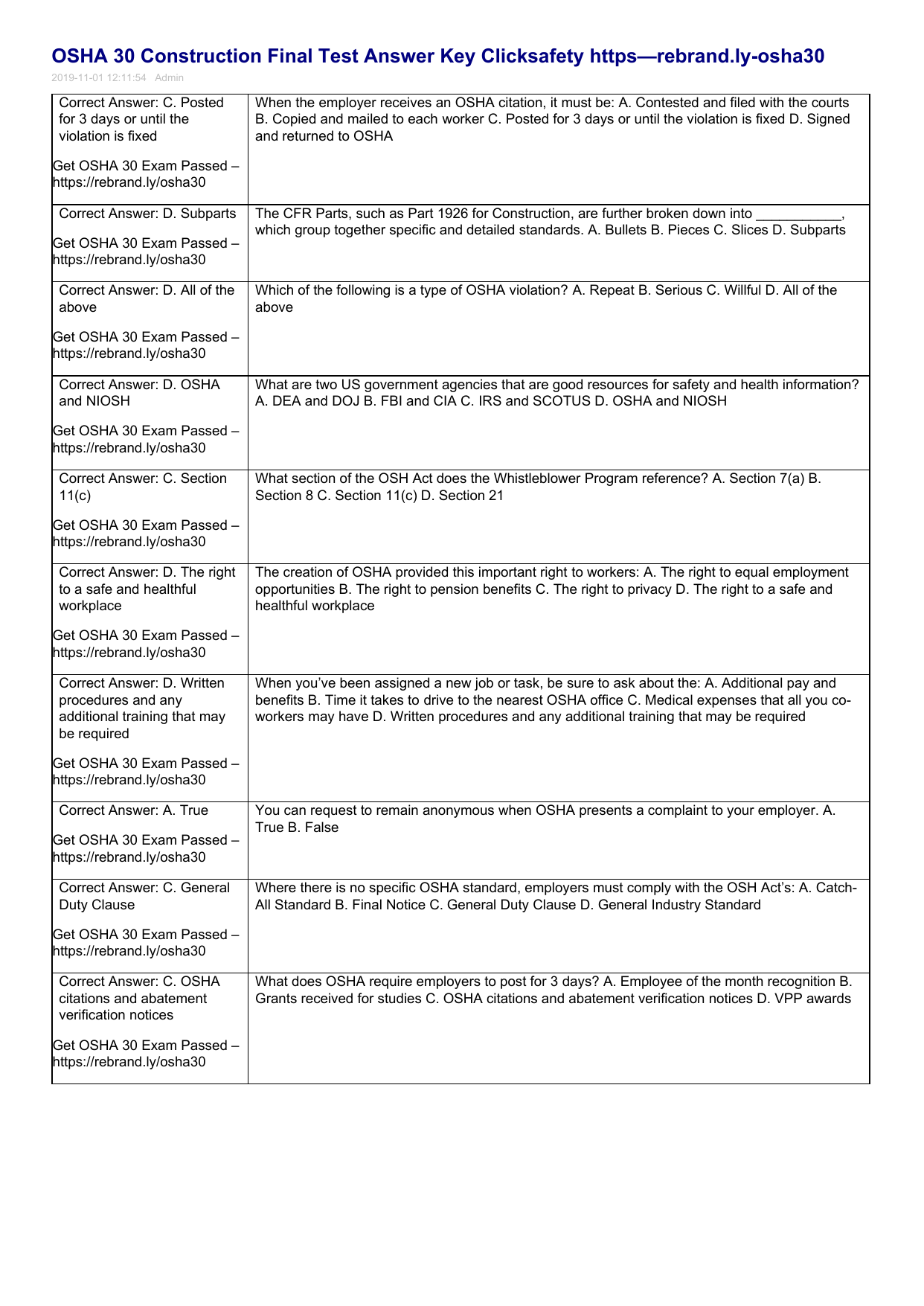

Image: mungfali.com

The OSHA 30 course equips individuals with the knowledge and skills to identify, assess, and control workplace hazards, contributing to a safer and healthier work environment. This training is valuable for individuals working in various sectors, including construction, manufacturing, healthcare, and government. Mastering these vital safety principles can not only save lives but also enhance productivity, reducing the cost of accidents and injuries. For many, passing the OSHA 30 exam is a stepping stone to career advancement, unlocking opportunities for leadership roles and greater responsibilities.

Navigating the Click Safety Labyrinth

Click safety, a crucial aspect of OSHA 30 training, delves into the intricacies of electrical safety with a focus on preventing accidents and injuries caused by electrical hazards. This section will provide a detailed exploration of the key concepts covered in the OSHA 30 syllabus related to click safety.

Understanding Electrical Hazards

The first step towards navigating click safety is understanding the nature of electrical hazards. Electricity is a powerful force, and when mishandled, it can lead to serious injuries or even fatalities. It’s essential to recognize the various types of electrical hazards and their potential consequences:

-

Electrical shock: This occurs when a person comes into contact with an energized electrical source, resulting in the passage of electrical current through their body. The severity of shock depends on the voltage and the duration of the contact.

-

Electrical burns: These are caused by heat generated from electrical current passing through the body. They can range from mild to severe depending on the amount of current and the duration of contact.

-

Arc flash: This is a sudden, intense explosion of electrical energy that occurs when an electrical current jumps across an air gap. It can cause severe burns, blast injuries and eye damage.

-

Arc blast: This is a similar phenomenon to arc flash, but it involves a much larger explosion of energy that can create significant damage and launch debris.

Applying the Lockout/Tagout Procedure

The Lockout/Tagout procedure is a crucial safety measure for ensuring that equipment and circuits are properly de-energized before any work is performed. This procedure helps prevent accidental energization of equipment, ensuring the safety of workers. It involves the following steps:

1. Preparation and Planning: Identify the specific equipment or circuit that needs to be de-energized, and gather the necessary lockout/tagout devices such as locks, tags and warning signs.

2. Isolation and De-energization: Disconnect the equipment or circuit from the power source, making sure it is completely de-energized before proceeding with the work.

3. Lockout/Tagout: Attach a lock and tag to the power source and equipment, making the equipment inaccessible and marking it as “do not operate.” This process ensures that no one can accidentally turn on the equipment during maintenance or repair.

4. Verification: Before starting work, verify that the equipment is indeed de-energized by using a voltmeter or a similar device.

5. Work Procedures: Carry out the maintenance or repair work as planned, ensure all employees understand the importance of isolating the equipment and enforcing the lockout/tagout procedures.

6. Removal of Lockout/Tagout: Once the work is completed, remove the locks and tags in reverse order, ensuring that the equipment is fully energized before releasing the locks. This step needs careful attention to ensure none of the locks remain, a common cause of accidents.

7. Release and Verification: After the locks are removed, verify that the equipment is re-energized and operational.

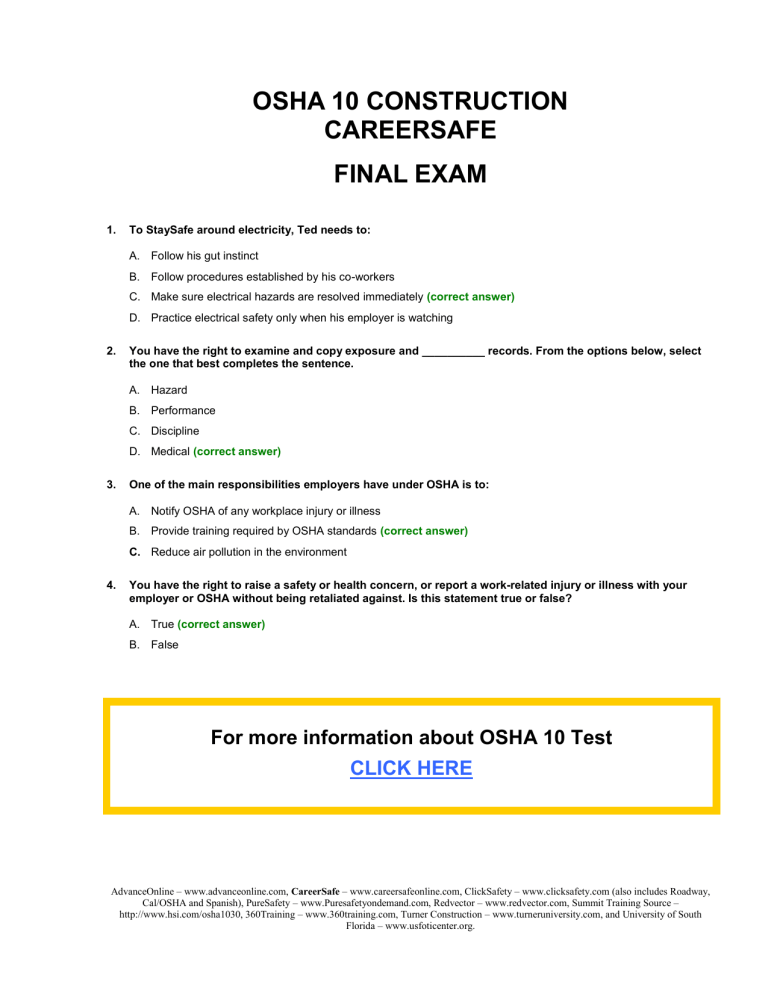

Image: trending584eut.blogspot.com

Safe Work Practices: A Crucial Foundation

Beyond Lockout/Tagout, implementing a set of safe work practices is essential to mitigate electrical hazards:

-

Use of Ground Fault Circuit Interrupters (GFCIs): GFCIs are safety devices that detect ground faults and interrupt electrical current, protecting individuals from electrical shock. Install GFCIs in areas where water or moisture is present, using them in bathrooms, kitchens, garages and outdoors.

-

Use of insulated tools: Employ insulated tools to handle electrical equipment and components, minimizing the risk of electrical shock.

-

Proper use of personal protective equipment: Wear appropriate personal protective equipment, such as gloves, eye protection, and footwear, when working with electricity.

-

Know your surroundings: Be mindful of your surroundings while working and watch out for electrical hazards, taking the necessary precautions to avoid contact with exposed wires or energized equipment.

-

Report any electrical hazards: Inform your supervisor immediately if you identify any unsafe electrical conditions or equipment.

Practical Tips for Conquering the OSHA 30 Click Safety Exam

Here is a compilation of strategies and tips aimed at maximizing your success in the OSHA 30 final exam, empowering you with the knowledge and confidence to ace it:

-

Review the OSHA 30 syllabus thoroughly: Understand the key concepts, terms, and topics covered in the course, focusing on the section dedicated to click safety.

-

Engage in active learning: Participate actively in classroom discussions, ask questions, and seek clarification to solidify your understanding.

-

Practice, practice, practice: Work through practice questions, exam simulations, and quizzes to reinforce your understanding of click safety principles.

-

Create a study schedule: Allocate specific time blocks for studying, ensuring you cover all the necessary material.

-

Seek help when needed: Don’t hesitate to seek help from your instructor or other professionals if you are struggling with a particular concept.

-

Get plenty of rest the night before the exam: Ensure you’re well-rested and mentally prepared to face the exam with a clear mind.

-

Don’t panic on exam day: Stay calm, read the questions carefully, and use your knowledge and skills to answer them to the best of your ability.

Answer Key Click Safety Osha 30 Final Exam Answers

Wrap Up: Equip Yourself for a Safer Future

The OSHA 30 final exam is a significant milestone in your journey towards becoming a safety-conscious professional. By understanding the principles of click safety as covered in this article, you can navigate the exam with confidence and equip yourself with the knowledge and skills to create a safer environment for yourself and your colleagues. Remember, a successful outcome is a testament to your commitment to safety, a testament to your professional growth, and a key to unlocking a future with fewer workplace accidents.

Now that you’re armed with the knowledge to succeed on your OSHA 30 final exam, take the next step! Share your insights with your colleagues, leading by example and fostering a culture of safety in your workplace. It’s time to embrace the power of knowledge and make a difference, one click safety practice at a time. Safe work always starts with you!