Ever wondered how your car’s engine knows when to fire, how much fuel to inject, or how fast to spin the engine? The answer lies within a complex network of electrical signals and sensors, all orchestrated by the Electronic Control Module (ECM), also known as the Engine Control Unit (ECU). The ECM, often referred to as the “brain” of the car, receives information from various sensors throughout the engine and chassis, then processes these signals to control engine operation. This intricate interaction is governed by the ECM’s wiring diagram, a blueprint that reveals the secrets of its internal circuitry. In this article, we’ll delve into the world of the Cat 40 pin ECM wiring diagram, uncovering the mysteries behind its connections and unlocking its practical significance for any automotive enthusiast.

Image: manualmanualtackett.z13.web.core.windows.net

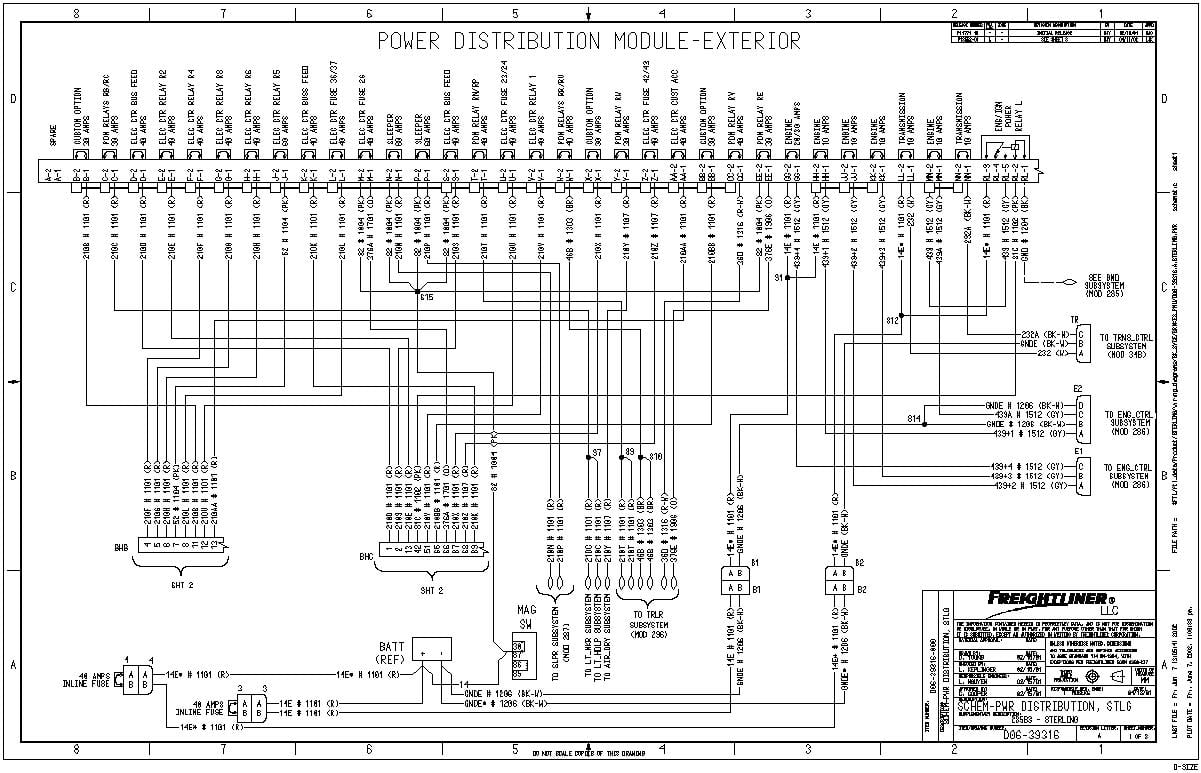

The Cat 40 pin ECM wiring diagram, a specialized schematic specific to certain Caterpillar engine models, is a valuable tool for understanding the ECM’s functions and troubleshooting potential issues. It depicts the intricate web of wires and connections that link the ECM to the engine’s sensors, actuators, and various other components. By understanding the diagram’s layout, you can diagnose faulty sensors, trace electrical pathways, and pinpoint potential short circuits or open circuits that might be affecting engine performance.

Navigating the Cat 40 Pin ECM Wiring Diagram: A Step-by-Step Guide

Navigating the Cat 40 pin ECM wiring diagram might seem daunting at first glance, but with a systematic approach, it becomes a relatively straightforward process. Here’s a breakdown of the steps involved:

1. Identifying the ECM Connector:

The first step is to locate the ECM connector, typically found in the engine compartment, often near the engine block or firewall. The connector will have a distinctive 40-pin layout, clearly visible on the diagram.

2. Pin Number Designation:

Each pin on the ECM connector has a unique number, ranging from 1 to 40. This numbering system is crucial for understanding the wiring diagram. Pins are usually numbered in sequence, starting from one corner of the connector and moving in a clockwise or counterclockwise direction. Carefully examine the wiring diagram to identify the pin numbering scheme used for your specific ECM.

Image: yarnium.blogspot.com

3. Decoding Wire Colors:

Each wire connected to the ECM is assigned a specific color code. The wiring diagram will usually feature a legend or chart that details the color code and its corresponding function. For example, you might see a wire labeled “Red/White,” which indicates a red wire with a white stripe. This color coding is essential for identifying the correct wires for troubleshooting or repairs.

4. Understanding Circuit Pathways:

The wiring diagram depicts the complete electrical pathway from the ECM to the corresponding sensor or actuator. Each circuit line typically includes the following information:

- Pin Number – the specific pin on the ECM connector where the wire is connected.

- Wire Color – the color code of the wire, helping you identify it in the engine compartment.

- Component Name – the name of the sensor or actuator that the wire connects to, such as ‘Crankshaft Position Sensor’ or ‘Fuel Injector.’

- Circuit Description – a brief description of the function of the circuit, explaining its role in the engine’s operation.

5. Tracing Circuits:

Once you’ve identified the pin and wire color corresponding to a specific component, you can follow the circuit path on the wiring diagram. The diagram will illustrate how the wire connects to other components, sensors, and actuators. This tracing allows you to identify the complete electrical path of a particular signal, providing invaluable insight into how the ECM controls engine functions.

Unlocking the Potential of the Wiring Diagram: Practical Applications

The Cat 40 pin ECM wiring diagram is not just a theoretical concept; it has countless practical applications, empowering automotive enthusiasts to diagnose technical issues and maintain the health of their vehicles.

1. Diagnosing Engine Problems:

The wiring diagram is the cornerstone of troubleshooting engine problems. When your vehicle exhibits unusual symptoms like misfiring, stalling, or sluggish acceleration, the wiring diagram becomes an indispensable tool. By examining the wiring diagram, you can pinpoint potential issues, such as a faulty sensor, a broken wire, or a short circuit. You can test the continuity of individual circuits, ensure proper signal transmission, and identify any faulty components.

2. Performing Repairs:

The wiring diagram is essential for accurate repairs. If you need to replace a sensor, actuator, or other electrical component, the diagram helps you understand the connections and wiring configurations. It ensures that you connect the new component correctly and avoid creating short circuits or open circuits that can damage the ECM or other electrical components.

3. Modifying or Upgrading Components:

If you’re inclined to modify or upgrade engine components, such as replacing your exhaust system with one featuring a high-flow catalytic converter, the wiring diagram will help you navigate the complex circuitry. It allows you to understand how the ECM interacts with these components, ensuring that your modifications are compatible and function seamlessly with the existing electrical system.

4. Upgrading Your Diagnostic Tools:

The Cat 40 pin ECM wiring diagram complements professional diagnostic tools. While scan tools provide valuable information about engine sensors and fault codes, their interpretation is greatly enhanced by referring to the wiring diagram. The wiring diagram reveals the connections behind the sensor data, helping you understand the root cause of the problem and plan your repair strategy.

Beyond the Basics: Advanced Concepts and Troubleshooting Techniques

As you gain confidence in using the Cat 40 pin ECM wiring diagram, you can delve deeper into more advanced troubleshooting techniques. These concepts can help diagnose and address more complex issues that might arise in your automotive journey.

1. Understanding Signal Types:

The Cat 40 pin ECM wiring diagram will often indicate the type of signal transmitted on each wire. The most common signals include:

- Analog Signals – These signals are continuously varying voltages or currents, reflecting changes in the sensor’s output. For example, a temperature sensor would generate varying voltages depending on the engine’s temperature.

- Digital Signals – These signals are binary values, either 0 or 1, typically used to control actuators like fuel injectors, solenoids, or relays.

- Pulse Width Modulation (PWM) Signals – These signals are used to control the duty cycle of an actuator, effectively controlling its operating intensity. For example, PWM signals can be used to control the amount of fuel injected into the engine.

2. Pinpointing Short Circuits and Open Circuits:

The wiring diagram is crucial for identifying short circuits and open circuits. If a circuit is short-circuited, the wire will have an unintended connection to ground or another power source, leading to faulty signal transmission and potential damage. Open circuits occur when a wire is broken or disconnected, causing a lack of signal flow to the ECM or actuator. Using a multimeter to test for continuity and resistance, you can readily diagnose open circuits and short circuits by tracing the circuit pathways.

3. Interpreting Fault Codes:

The wiring diagram pairs with your scan tool to interpret fault codes. While scan tools display numerical codes indicating specific problems, the wiring diagram will elucidate the meaning behind these codes, helping you understand the sensor or component responsible and pinpoint the location of the issue. It provides a more detailed perspective than solely relying on the generic codes displayed by the scan tool.

Resources for Delving Deeper:

The Cat 40 pin ECM wiring diagram is a fundamental tool for anyone who wants to understand how their car’s engine works and how to maintain it. There are several valuable resources available to help you further your knowledge:

- Caterpillar Service Manuals – Caterpillar offers comprehensive service manuals for their engine models, including detailed wiring diagrams and troubleshooting information. You can purchase these manuals directly from Caterpillar or through authorized dealers.

- Online Forums and Communities – Forums like “TheDieselStop” and “MachineryTrader” host active communities of Caterpillar enthusiasts who share their knowledge and experience with ECM wiring diagrams and troubleshooting techniques.

- Automotive Repair Professionals – Local automotive repair technicians and specialists can provide specific guidance and assistance with the Cat 40 pin ECM wiring diagram and other engine-related issues. Seek their expertise if you encounter challenging troubleshooting scenarios.

Cat 40 Pin Ecm Wiring Diagram

Conclusion: A Gateway to Automotive Mastery

The Cat 40 pin ECM wiring diagram is more than just a collection of lines and symbols; it’s a key to unlocking the mysteries of your vehicle’s engine control system. By understanding the wiring diagram’s layout and deciphering its intricate connections, you can elevate your automotive expertise, confidently diagnose engine issues, and ensure your vehicle runs smoothly. Whether you’re an experienced enthusiast or just starting to explore the world of auto mechanics, mastering the Cat 40 pin ECM wiring diagram is an invaluable investment in your automotive knowledge.