Imagine yourself on a construction site, the sun blazing down, sweat dripping, and the air filled with the rhythmic thrum of powerful machinery. You’re the operator, a master of your domain, ready to tackle any project – but then, a wrenching sound emanates from your trusty John Deere 310A backhoe. Suddenly, that rhythmic thrum becomes a guttural groan, and a sense of dread washes over you. What now? Fear not, intrepid operator, for unlocking the secrets of the John Deere 310A backhoe parts diagram can empower you to diagnose and solve any mechanical hiccup.

Image: deeremanuals.com

This comprehensive guide will delve into the intricate world of the John Deere 310A backhoe parts diagram, revealing its nuances and empowering you to confidently navigate the realm of repairs and maintenance. Whether you are a seasoned veteran or a novice enthusiast, this guide will be your unwavering companion, equipping you with the knowledge to conquer any challenge that may arise.

Decoding the Essentials: A Breakdown of the John Deere 310A Backhoe Parts Diagram

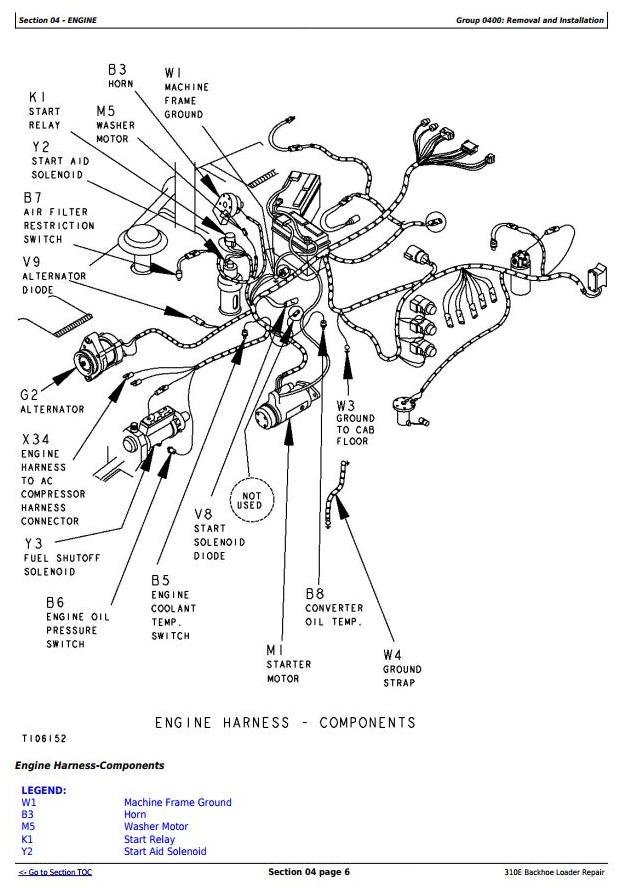

The John Deere 310A backhoe parts diagram is your indispensable roadmap, a visual lexicon that translates the complex language of machinery into a comprehensible framework. It is a meticulously crafted schematic that maps out the intricate network of parts within your machine, revealing their precise positions and relationships.

Think of it like a blueprint for a house, except instead of walls and windows, you’ll find hydraulic cylinders, transmission components, and an array of critical subsystems. It is a visual representation of the machine’s anatomy, allowing you to identify, locate, and understand the function of each part.

Navigating the Labyrinth of Parts

Let’s begin with the fundamental components that shape the John Deere 310A backhoe’s formidable capabilities.

- The Engine: This powerhouse propels the machine, providing the raw energy that drives its various systems.

- Hydraulic System: The heart of the backhoe’s operation, this intricate network of pumps, valves, and cylinders harnesses hydraulic fluid to generate the force needed for lifting, digging, and maneuvering.

- Transmission: This crucial component transmits power from the engine to the wheels, allowing the backhoe to move with precision and control.

- Backhoe Attachment: The iconic digging arm, this system comprises multiple hydraulic cylinders that enable digging, lifting, and material handling.

Demystifying the Diagram: Key Elements and Their Significance

Each part on the diagram is assigned a unique number, a language that unlocks the secrets of the John Deere 310A backhoe. This numbering system, akin to a secret code, allows professionals and enthusiasts to seamlessly communicate and identify parts. You’ll find corresponding part numbers in manuals and online databases, enabling you to order replacements with utmost precision.

Here’s how the diagram helps you navigate the intricate world of repair and maintenance:

- Identifying the culprit: When a part malfunctions, the diagram becomes your guide to pinpoint the exact location and identify the problem with clarity.

- Ordering the right replacement: With the part number readily available, you can order the correct replacement part with confidence, avoiding costly mistakes and delays.

- Understanding the flow of power: By tracing paths and connections on the diagram, you can gain a thorough understanding of how different parts work together, facilitating smoother troubleshooting and maintenance.

Image: spare.avspart.com

Maintaining Harmony: A Guide to Preventative Care

The John Deere 310A backhoe, like any powerful machine, requires regular attention to maintain peak performance and longevity. The parts diagram can be your ally in this endeavor, offering a roadmap for preventative maintenance.

By carefully examining the diagram, you can identify critical components that require regular inspection and lubrication. This includes:

- The hydraulic system: Regularly checking fluid levels and ensuring proper lubrication can prevent premature wear and tear, safeguarding the core of your machine.

- Transmission system: Regular maintenance of this essential component, including oil changes and adjustments, is crucial for smooth operation and optimal lifespan.

- Backhoe attachment: Inspecting and lubricating the various hydraulic cylinders and linkage pins is vital to maintain digging power and prevent costly failures.

Harnessing the Power of Information: Utilizing the Parts Diagram for Effective Troubleshooting

Now that you’ve gained a fundamental understanding of the John Deere 310A backhoe parts diagram, let’s dive into practical applications. Imagine you’re on the job, and your backhoe suddenly begins acting up.

Here’s how the parts diagram can be your key to rapid diagnosis and resolution:

- Identifying the Source: Is the backhoe refusing to dig, unable to lift, or experiencing a loss of power? The parts diagram helps you trace the chain of components responsible for these functions, revealing the potential culprit.

- Testing and Verification: Equipped with this knowledge, you can systematically test each component in the chain, focusing your efforts on the most likely sources of the problem.

- Rapid Resolution: By pinpointing the culprit, you can rapidly order the necessary replacement part and get your machine back up and running with minimal downtime, saving you time, money, and headaches.

Mastering the Art of Repair: Practical Tips for Success

The John Deere 310A backhoe parts diagram is an excellent starting point, but the real skill lies in applying that knowledge effectively. Consider these practical tips:

- Safety First: Always prioritize safety when working on heavy machinery. Wear appropriate protective gear, disconnect power sources, and follow manufacturer guidelines.

- Thorough Inspection: Before tearing into your backhoe, conduct a thorough inspection to identify any obvious issues or signs of wear and tear on the suspect components.

- Consult the Manual: The factory service manual provides detailed instructions on procedures, torque specifications, and troubleshooting steps, making your repair process more efficient and safer.

Navigating the Digital Age: Online Resources and Communities

You are not alone! The digital world is brimming with online resources and communities dedicated to the John Deere 310A backhoe.

- John Deere Website: The official John Deere website offers detailed parts diagrams, service manuals, and parts ordering details directly from the manufacturer.

- Online Forums: Forums like TractorByNet and Backhoe Forum provide valuable insights from fellow operators who have tackled specific problems, offering tips, tricks, and shared experiences.

- YouTube: Countless informative videos provide visual demonstrations of troubleshooting and repair processes, giving you a hands-on perspective.

John Deere 310a Backhoe Parts Diagram

Conclusion: The Power of Knowledge

The John Deere 310A backhoe parts diagram, when coupled with practical knowledge and available resources, becomes a powerful tool for any operator. It not only unveils the secrets of the machine’s inner workings but also empowers you to anticipate problems, diagnose issues, and handle repairs with confidence.

This guide has equipped you with the foundational knowledge to unlock the potential of your John Deere 310A backhoe. Now, go forth, armed with this invaluable knowledge, and conquer any mechanical challenge that comes your way. Remember, the path to mastery is paved with understanding, and the John Deere 310A backhoe parts diagram is your roadmap to success!