Imagine a world where starting a large motor is as simple as flipping a switch. The jolt of power, the massive torque, and the smooth operation, all without overwhelming the electrical grid. This is the power of the star-delta motor connection, a design that’s reshaped industrial processes and minimized energy waste. But understanding this ingenious system can feel like deciphering a complex puzzle. But fret not, this guide will unveil the secrets of star-delta connections, providing a clear, accessible path to mastering this essential electrical engineering skill.

Image: mydiagram.online

But what exactly is a star-delta connection and why should you care? In short, it’s a clever way to start up powerful three-phase motors with reduced starting current, a crucial advantage in many industrial settings. Let’s dive into the details and unravel this fascinating electrical marvel.

Understanding the Basics

At the heart of the star-delta connection lies a simple yet elegant concept: changing the motor winding configuration to control starting current. Think of it like adjusting a water valve: you can restrict the flow at the start to prevent a surge, then open it fully for a smooth, powerful operation.

Let’s break it down:

- Star Connection: In this configuration, the motor winding ends are connected in a “star” shape, with one end of each winding joined at a common point called the neutral. The line voltage (voltage across the supply) is √3 times the phase voltage (voltage across each winding).

- Delta Connection: Here, the winding ends are connected in a “delta” shape, forming a closed loop. The line voltage and phase voltage are equal.

The Star-Delta Connection: A Starting Advantage

The key to the star-delta connection lies in its ability to control starting current. During the initial start-up, the motor is connected in a star configuration. This reduces the voltage applied to the windings, lowering the starting current. Think of it as a “gentle start” for your motor.

Once the motor has gained momentum, the connection switches to a delta configuration. This increases the voltage across the windings, allowing the motor to reach its full operating speed. It’s like switching from a “low gear” to a “high gear” for maximum power.

Practical Applications: Where Star-Delta Shines

Now that we’ve unraveled the mechanics, let’s explore the real-world applications where star-delta shines. Here’s where this ingenious connection truly earns its stripes:

- Reducing Starting Current: This is the star-delta connection’s primary advantage. Lower starting currents mean less strain on the electrical system, preventing voltage dips and protecting sensitive equipment.

- High-Power Motors: This connection is particularly beneficial for large motors found in industrial settings, from conveyors and pumps to mining operations.

- Improving Efficiency: The reduced starting current translates into lower energy consumption, leading to improved efficiency and cost savings.

- Protecting the Motor: By minimizing starting stress, star-delta connections can extend the lifespan of your motors, reducing maintenance costs.

Image: antekel.blogspot.com

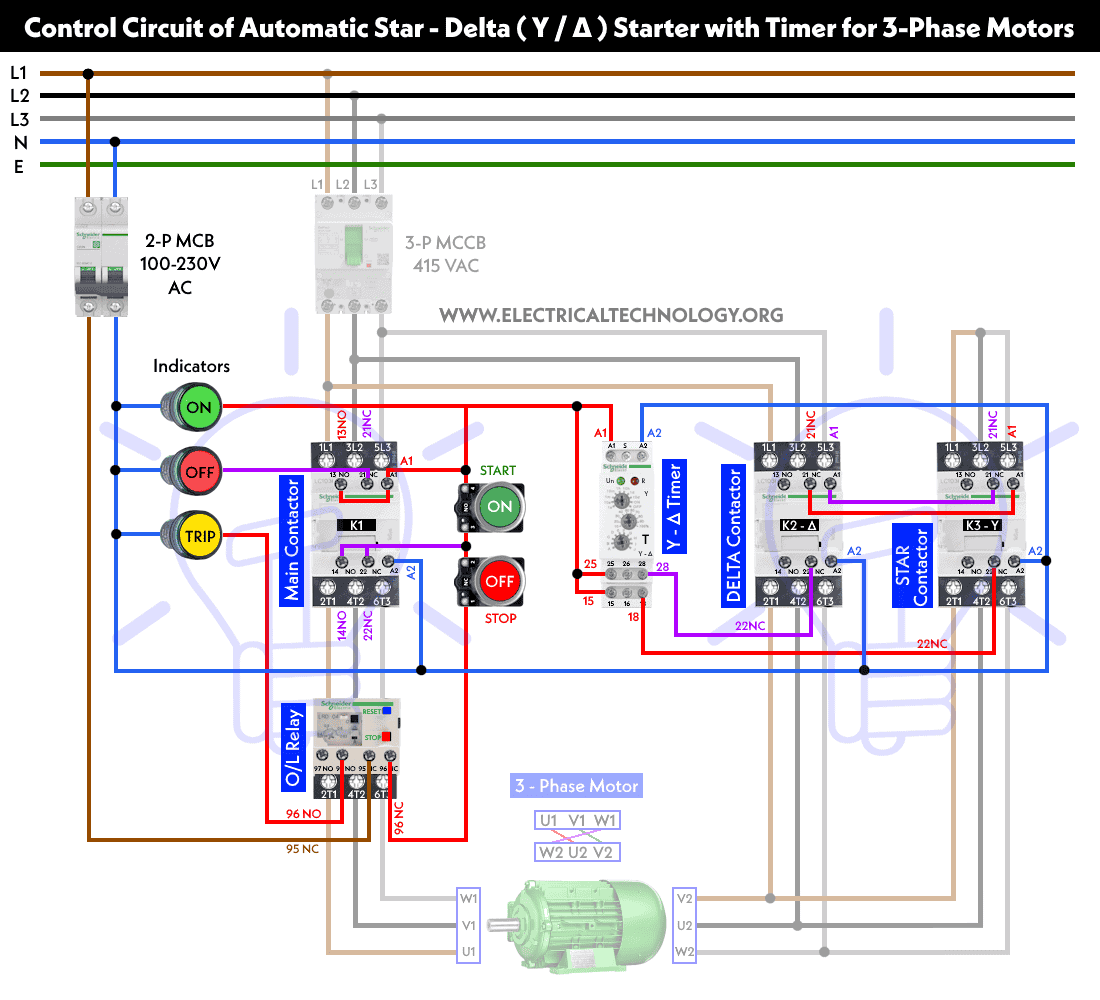

The Benefits of Using a Diagram

Here’s where things get even more interesting. Forget about complicated explanations; visual diagrams bring the star-delta connection to life:

- Crystal-Clear Illustration: Diagrams provide an intuitive visual representation of the connection points, making the concept much easier to grasp.

- Step-by-Step Guidance: Well-designed diagrams can illustrate the entire switching process, from star to delta, making implementation a breeze.

- Troubleshooting Aid: If something goes wrong, diagrams offer a clear roadmap for identifying potential issues and resolving them swiftly.

Star-Delta Connection Diagrams: Your Visual Guide

The beauty of star-delta connections lies in their simplicity, and that simplicity shines through in their diagrams.

The Fundamental Diagram

Visualize three sets of motor windings (U, V, and W) marked with start (S) and finish (F) points.

- Star Connection: In a star configuration, connect the finishing ends (F) of each winding together at a single point, labeled “N” (Neutral). The remaining starting ends (S) will be connected to the external power supply.

- Delta Connection: Directly connect the finishing ends of winding U to the starting end of winding V. Similarly, link the finish of V to the start of W and finish of W to the start of U. This creates a closed loop, forming a “delta.”

The Switching Sequence

A typical star-delta diagram includes a switch or contactor to manage the shifting between these configurations. It will show:

- Start position: The contactor connects the motor in a star configuration.

- Run position: As the motor accelerates, the contactor switches to the delta configuration, ensuring full power.

Important Considerations

- Voltage Levels: Pay close attention to the voltage levels used in your circuit. Star-delta connections are designed for specific voltage ranges.

- Motor Specifications: The motor’s nameplate should detail its winding configuration, starting current, and recommended connection methods.

Mastering Star-Delta Connections: Practical Tips

Armed with the knowledge and visuals, let’s empower you to confidently implement star-delta connections with practical tips:

- Consult the Motor Manual: Never skip this crucial step. It contains vital information on suitable connections and operating parameters.

- Plan Your Connections: Before making any electrical connections, make a meticulous plan, ensuring you understand the wire colors and terminal positions.

- Use High-Quality Components: Quality contactors and relays are essential for reliable switching operations and safe operation.

- Test Thoroughly: After completing the connections, test the motor thoroughly under controlled conditions.

Safety First: Always Exercise Caution

Dealing with high-voltage electricity requires utmost caution. Here’s a safety checklist:

- De-energize the Circuit: Ensure that the power supply to the motor is completely disconnected before working on the connections.

- Use Personal Protective Equipment (PPE): Always employ appropriate safety gear, including insulated gloves, eye protection, and a non-conductive mat.

- Familiarize Yourself with Safe Practices: Stay up to date on relevant electrical safety regulations and practices.

Stay Informed: The Electrical Engineering Landscape

The world of electrical engineering is constantly evolving, with innovations driving greater efficiency, safety, and sustainability.

- Industry Trends: Keep a pulse on industry trends and advancements in motor control technologies.

- Software and Simulation: Utilize software tools for circuit simulation and analysis, providing valuable insights and streamlining your design process.

3 Phase Star Delta Motor Connection Diagram Pdf

Conclusion: Your Journey to Electrification

The star-delta motor connection is a testament to human ingenuity, offering a simple yet powerful solution to enhance efficiency and safety in industrial applications. Equipped with this comprehensive guide, you’ll be ready to tackle star-delta connections with confidence. Let this knowledge ignite your passion for electrical engineering and drive your future success!

This journey is not just about understanding the star-delta connection; it’s about embracing the possibilities it unlocks. Now, go forth and explore the electrifying world of motor control!