The heart of any heavy-duty truck lies in its engine, and the CAT C15 engine is a powerhouse known for its durability and performance. But even the most robust machines can experience hiccups, and when they do, understanding the intricate network of wiring within the Electronic Control Module (ECM) is crucial for accurate diagnosis and troubleshooting. Luckily, the CAT C15 ECM wiring diagram acts as a map, guiding technicians through the complex pathways that control the engine’s vital functions.

Image: www.autowiringdiagram.net

This diagram is more than just a collection of lines and symbols; it’s a powerful tool that empowers mechanics to pinpoint the source of issues ranging from erratic engine behavior to malfunctioning sensors. It’s also essential for understanding the interconnectedness of the engine’s various systems, helping to ensure efficient repair and optimal performance.

Decoding the ECM Wiring Diagram: Understanding the Language of the Engine

The CAT C15 ECM wiring diagram, often presented in PDF format, may seem daunting at first glance, filled with intricate lines and cryptic symbols. But fear not, for a thorough understanding of this diagram is the key to unlocking the secrets of your engine’s electrical system.

The Anatomy of the Diagram: Navigating the Components

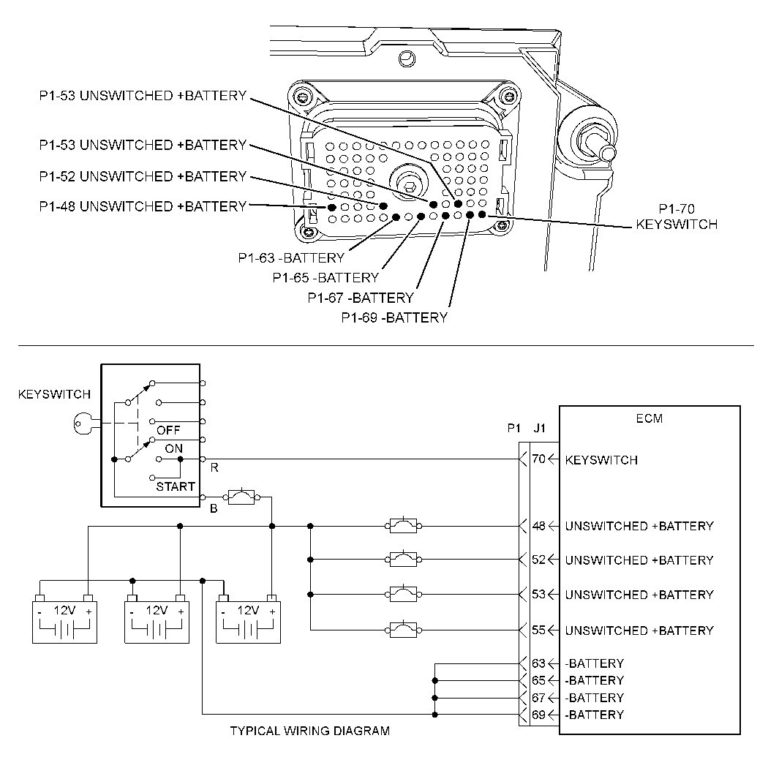

The diagram essentially serves as an electrical schematic of the ECM, providing a visual representation of the various components and their connections. Here’s a breakdown of the key elements you’ll encounter:

-

ECM (Electronic Control Module): The brain of the operation, the ECM receives input from numerous sensors and actuators, calculating and controlling engine parameters for optimal performance. It’s depicted as a central box on the diagram.

-

Sensors: These are the eyes and ears of the engine, providing the ECM with vital information about its operation. Examples include:

- Temperature Sensors: Track engine temperature, oil temperature, coolant temperature, etc.

- Pressure Sensors: Monitor oil pressure, fuel pressure, intake manifold pressure, etc.

- Position Sensors: Determine crankshaft position, camshaft position, throttle position, etc.

- Speed Sensors: Measure engine speed, wheel speed, etc.

-

Actuators: These are the engine’s muscle, responding to ECM commands to control various functions. Examples include:

- Fuel Injectors: Deliver precise amounts of fuel to the cylinders.

- Turbochargers: Boost engine power by forcing more air into the cylinders.

- Solenoids: Control various functions including fuel shutoff, transmission shifting, and other engine functions.

-

Wiring: The diagram shows the intricate network of wires that connect all these components to the ECM. Each wire represents a specific circuit carrying electrical signals to and from the ECM.

-

Color Coding: Wires are often color-coded for easy identification, allowing technicians to quickly trace circuits and locate specific connections.

Interpreting the Symbols: Unlocking the Mysteries

The ECM wiring diagram utilizes a standardized set of symbols to represent each component and connection, making it universally understandable. Understanding these symbols is crucial for accurately interpreting the diagram.

-

Component Symbols: Specialized symbols represent various engine parts like sensors, actuators, and even relays.

-

Wire Symbols: Lines represent wires, with different line thicknesses or types often indicating different wire gauges or types.

-

Connection Symbols: Circles or dots represent connections between components, with numbers or letters indicating specific terminals or pins.

Image: diagrammanualbaader.z19.web.core.windows.net

Harnessing the Power of the Diagram: Its Practical Applications

The CAT C15 ECM wiring diagram becomes your indispensable guide when troubleshooting engine issues. Here’s how it can help you pinpoint the source of problems:

-

Trace Circuits: By following the wires on the diagram, you can trace the path of electrical signals from sensors to the ECM and from the ECM to actuators. This allows you to identify any potential points of failure, such as broken wires, faulty connections, or damaged components.

-

Identify Faulty Components: If you suspect a specific sensor or actuator is malfunctioning, the diagram helps you pinpoint which circuit is responsible by revealing the associated wiring and connections.

-

Test Connections: The diagram guides you in testing the continuity and voltage of various circuits, enabling you to confirm whether they are functioning correctly.

-

Diagnose Specific Codes: Engine fault codes are often linked to specific circuits or components mentioned in the wiring diagram. By referencing the relevant sections, you can quickly determine the root cause of the code.

The Importance of a CAT C15 ECM Wiring Diagram: Beyond Diagnostics

While the primary function of the ECM wiring diagram is for troubleshooting, it plays a crucial role in a range of other applications:

1. Pre-emptive Maintenance: Preventing Problems Before They Arise

The diagram allows you to visualize the entire electrical system and identify potential weaknesses before they lead to breakdowns. By regularly inspecting wires and connectors, and testing the functionality of sensors and actuators, you can proactively prevent serious issues.

2. Modifying and Upgrading the Engine: A Guide for Customization

For those looking to customize or upgrade their CAT C15 engine, the wiring diagram becomes essential. It provides valuable information about the existing wiring and connections, allowing you to make informed decisions about potential modifications without compromising the engine’s integrity.

3. Training and Education: Unveiling the Secrets of the Engine’s Electrical System

Whether you’re a seasoned mechanic or an aspiring technician, the CAT C15 ECM wiring diagram serves as a valuable educational tool. By studying it, you can gain a deeper understanding of the engine’s electrical system, expanding your knowledge and expertise.

Navigating the Digital Landscape: Sourcing Your ECM Wiring Diagram

The internet has revolutionized access to information, providing a wealth of resources for finding the CAT C15 ECM wiring diagram you need. Here are a few reliable avenues to consider:

-

CAT Dealer Websites: Head to the official CAT website or your authorized CAT dealer’s website. They often provide access to downloadable service manuals and technical documents, including ECM wiring diagrams.

-

Online Forums and Communities: Many online forums dedicated to truck mechanics and diesel enthusiasts offer a plethora of resources, including shared wiring diagrams. Be sure to verify the reliability of the source before downloading any files.

-

Specialized Websites: Several websites cater specifically to heavy-duty truck repair and maintenance. They often offer access to wiring diagrams and other technical documents for a subscription fee.

A Word of Caution: The Importance of Safety

While the CAT C15 ECM wiring diagram is a valuable tool, always remember that working with electrical systems can be dangerous. Here are some vital precautions:

-

Disconnecting Power: Always disconnect the battery before working on any electrical components to prevent the risk of shock.

-

Safety Gear: Use appropriate protective gear like insulated gloves and safety glasses to protect yourself from potential hazards.

-

Professional Expertise: If you’re not comfortable working with electrical systems, seek the help of a qualified mechanic to ensure the safety of yourself and your vehicle.

Cat C15 Ecm Wiring Diagram Pdf

Conclusion: Master the Wiring Diagram, Master the CAT C15

The CAT C15 ECM wiring diagram is a powerful tool that empowers technicians to diagnose engine problems, perform preventative maintenance, and even modify the engine’s functionality. By understanding the language of the diagram and its practical applications, you can unlock the secrets of the CAT C15’s electrical system, leading to a more reliable, efficient, and long-lasting engine. So, dive in, explore the wiring diagram, and unlock the full potential of your CAT C15.